Having spent his whole life in the hair care and cosmetics industry, Shailesh Bhavanbhai knows how important it is to follow the latest fashion trends. Yet, as an entrepreneur, he also knows the power of bucking the trend. While few South African entrepreneurs dare to compete with cheap imports from the East by establishing local manufacturing, Shailesh decided to do just that.

Two years ago, Shailesh invested all he had, including his almost four decades of experience and knowledge, into starting up his own small factory in Crown Mines, Johannesburg. There, with a team of 16 employees, he produces hairstyling products for his four own brands, Top Notch, Belleza, Ayur and Sage. Ironically, it was competition from China that pushed him back into manufacturing, Shailesh explains.

Since 2010, he had been importing hair accessories and salon equipment for the local market. But over the years competition in the trade became increasingly fierce as Chinese traders started importing directly into South Africa. Shailesh saw that the only way to grow was to diversify into a segment less vulnerable to cheap imports. Hairstyling chemicals are mass produced in the East, but they typically follow American formulas that are not as suited to local hair types. Drawing on his lifelong knowledge of South African local hair care since he was a child, Shailesh saw an opportunity and seized it.

Shailesh’s journey in the hair-care business began at his parents’ barber shop and hair-care business. Straight after school, he went to work in the retail industry and by the age of 20 he was managing a supermarket. With the help of his father, Shailesh started his own cosmetic shop in Johannesburg. Later, he joined his elder brother in his business called Charlie Parkers, a pioneer retail chain for ethnic hair care products. It was during this time that Shailesh got his first taste of manufacturing when they started producing their own branded products.

In the early 2000s Charlie Parkers was sold to a bigger company, but Shailesh never left the cosmetics industry. For a number of years, he worked with a franchise operation that specialised in hair extensions successfully managed to grow it into the leading brand in KwaZulu-Natal and the Eastern Cape.

Despite these achievements, Shailesh always wanted to build his own business. In 2010, he started importing hair accessories and salon equipment. By this time in his career, he knew the challenges and risks of manufacturing and starting a brand from scratch. However as imports became increasingly saturated, the case for producing locally specialised cosmetics grew stronger.

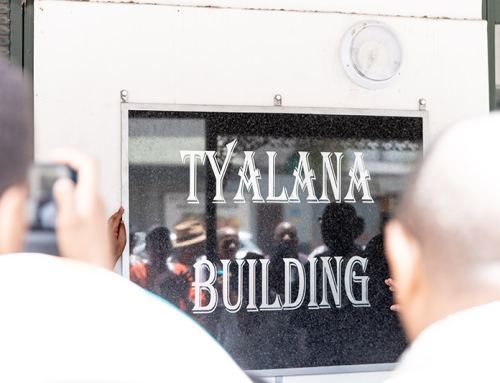

In 2023, Shailesh took the leap and opened his factory doors by starting with a contract to package products for a local independent brand seeking a manufacturer. This contract gave him the anchor to establish his manufacturing plant while he embarked on the intense process of launching his own brands.

Starting such a capital-intensive venture was very difficult, admits Shailesh. But he had three key advantages. The first was a factory manager who stayed with him ever since his first stint in manufacturing and brought invaluable expertise and encouragement. “He knew all the formulas and always urged me to start manufacturing again,” says Shailesh. The second advantage was his vast network in the cosmetics industry. Many retailers were willing to put his new brands on their shelves because they knew and trusted him.

The third advantage was his relationship with Business Partners Limited, who provided crucial financial support. They backed his fledgling factory with a working-capital loan and later with a second loan for the purchase of manufacturing equipment. Shailesh credits them for taking the time and effort to understand his business. “The banks just want to look at paper, whereas Business Partners Limited actually came out to see us, which I respect. They’ve seen what my business is about and they understand it,” he says.

Although it is still early days for the new factory, Shailesh sees steady growth ahead, not only in the sales of his four brands, but also in expanding his contract manufacturing client base. Once his brands are established in the local market, his next goal is to become an exporter himself.